Crane Wire Rope

Wire rope used for each crane and construction machinery require various characteristics depending on each application. We line up specific products in compliance with such characteristics other than the products based on GB/T or DIN and others.

Crane wire rope plays an important role in ensuring a smooth conduct of work processes in harbors, off-shore platforms or various other applications where cranes are needed. Whether you need tower crane wire rope or offshore crane wire rope, galvanized or stainless steel wire rope, you will find the optimal solution in our company.

Features:

- High resistant to corrosion.

- Excellent ductility for optimal fatigue properties on rope level.

- Highest breaking strength leading to outperforming steel crane wire ropes.

- Excellent impact resistance owing to its radially elastic rope structure for absorbing dynamic force easily.

- Superb flexibility ensures excellent spooling conditions in multiple layer winding and all hoisting processes.

- High cost-effectiveness taking advantages of its strong and durable structure to reduce downtime and maintenance cost.

- Rotating and rotation resistant ropes are available.

- Optional compacted and non-compacted ropes.

Details:

- Material: high carbon steel wire, galvanized steel wires or stainless steel wires.

- Standard: complying with EN-10264 or other custom specs.

- Tensile strength: 1370N/mm2 up to 2260N/mm2.

- Coating: bright phosphate wire, galvanized wire or other custom coatings.

- Wire diameter: 0.3mm to 4mm or thicker diameter upon request.

- Structure: rotating & rotation resistant wire ropes, compacted & non-compacted wire ropes.

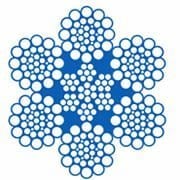

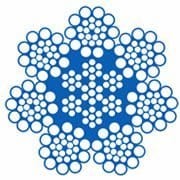

Feature:

- Eight compacted strands.

- Parallel-laid structure.

- Excellent crush resistance.

- Extremely high breaking force.

- Applications: boom crane, dockside cranes, offshore cranes and overhead cranes.

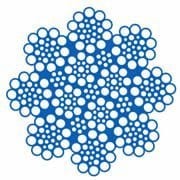

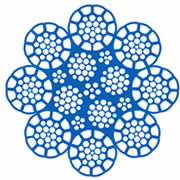

Feature:

- Eight compacted strands.

- Plastic encapsulated core.

- Ideal for multi-layer coiling.

- Reduced stretch.

- Application: boom crane, unloader crane, dockside crane, offshore crane and overhead crane.

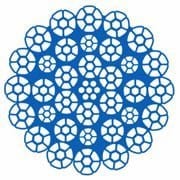

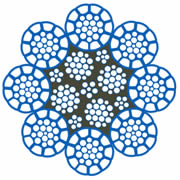

Feature:

- Eighteen compacted strands.

- Optional plastic encapsulated core.

- Rotation resistant.

- Application: tower crane, mobile crane, boom crane, dockside crane, offshore crane and overhead crane.

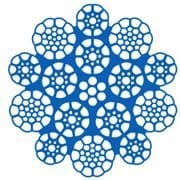

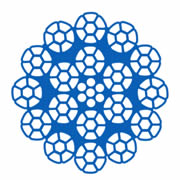

Feature:

- Eighteen compacted strands.

- Rotation resistant.

- Ideal for single-fall and multi-reeve applications.

- Application: offshore crane, mobile crane, overhead crane.

Feature:

- Eight regular strands

- Parallel lay structure.

- Fully lubricated.

- Non-rotating.

- Application: electrical hoist, twin hoist, lifting device.

Feature:

- Ten compacted outer strands

- Parallel lay structure.

- Fully lubricated.

- Non-rotating

- Application: electrical hoist, twin hoist, lifting device. Not suitable for overhead cranes and using with swivels.

Feature:

- Thirty-four compacted strands.

- Low rotation.

- Optional plastic encapsulated core.

- Application: tower crane, electrical hoist, mobile crane, boom crane, offshore crane and overhead crane.

Feature:

- Six compacted strands.

- Non-rotating.

- Optional plastic encapsulated core.

- Excellent crush resistant.

- Application: container crane, tower crane, boom crane, unloader crane, dockside cranes, offshore crane and overhead crane

Feature:

- Six strands. .

- Durable design.

- High flexibility.

- Application: container crane, clamshell crane, tower crane, mobile crane and overhead crane.

Feature:

- Six strands.

- Good balance between wear resistance and flexibility.

- Fully lubricated.

- Application: container crane, tower crane, mobile crane, overhead crane and offshore crane.

Feature:

- Six special wire strands.

- Hammer swaged for high damage resistance.

- Smooth surface area reduces wear of sheaves and drums.

- Application: container crane, tower crane, offshore crane and clamshell crane.

Feature:

- Seven outer strands.

- Good spooling in single layer & multi-layer winding applications.

- Application: overhead crane and various high cycle applications.

Tips:

When you are picking up crane wire ropes, make sure that the breaking strength of new wire ropes is five times the sizes of the largest load for lifting applications and three times for pulling applications.