LKS-Reliable to the core

Gas & Oilfield Wire Ropes

Gas & oilfield wire ropes with higher breaking strength, excellent flexibility, better rotation resistance and extended lifespan are urgently needed with the development of gas and oil industry. These steel wire ropes are designed to increase the productivity on rigs and minimize downtime.

For the oil and gas industry, finding and accessing new sources of energy depends on global availability of extraordinarily tough drilling lines that let you explore and extract resources buried deep beneath the surface. Union drilling lines are like our engineers and personnel – with you day-in, day-out helping you produce on the rig. Offshore, land, workover or whatever the rig may be – we know the right rope for your application. You can count on Union’s outstanding quality and support wherever your rig may be.

- Drilling.

- Marine riser tensioner.

- Offshore cranes and winches.

- Platforms.

- Deep water mooring.

- Various geophysical applications.

Details:

- Material: high carbon wires or other custom materials.

- Standard: complying with API standards.

- Tensile strength: 1370N/mm2 up to 2260N/mm2.

- Coating: zinc coating or other custom coating upon request.

- Styles: regular, swaged, compacted or non-compacted.

Feature:

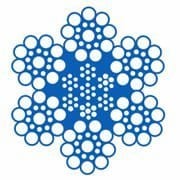

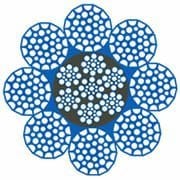

- For rotary drilling line.

- Six seale strands.

- Standard drill line.

- Complying with API 9A.

- A combination of abrasion and fatigue resistance.

Feature:

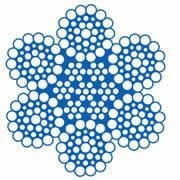

- For rotary drilling line.

- Six seale strands.

- Plastic impregnated rope for distributing internal stresses and keeping dirt out.

- Can withstand sunlight, cold weather and high operating temperature.

Feature:

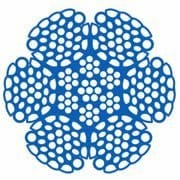

- For rotary drilling line.

- Six compacted strands.

- Plastic impregnated core for min internal nicking.

- Smoother surface.

- More metallic area with increased strength, excellent wear and fatigue resistance.

Feature:

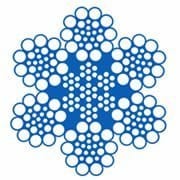

- For mast raising line.

- Six high performance strands.

- Meet API specification.

- Right regular or right lang lay structure.

- With independent wire rope core.

Feature:

- For tubing line.

- Six swaged strands.

- High density with greater crushing and abrasion resistance.

- Independent wire rope core.

Feature:

- For tubing line.

- 6 × 26 strands.

- Excellent crush and fatigue resistance.

- Increased inner wire number for high stability.

- Independent wire rope core.

Feature:

- For tubing line.

- Special nine swaged high density strands.

- Greater and smoother surface than GOWR-631SW.

- Extra drum crushing resistance.

Feature:

- For sand line.

- Six steel strands.

- With fiber core.

- Designed for harsh conditions.

- Lager outer wires.

- Excellent abrasion and fatigue resistance.

- Right regular lay.

Feature:

- For sand line.

- Five swaged strands for greater strength per diameter.

- With fiber core.

- High density construction.

- Greater surface area and less scrubbing.

Feature:

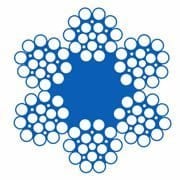

- For offshore applications.

- Eight compacted strands.

- Plastic impregnated core.

- Greater surface area than GOWR-629C.

- Less sheave wear.

- High strength.

Feature:

- For cable tool line.

- Six high performance strands.

- With fiber core.

- Added filler wires for increased bending fatigue resistance.

Feature:

- For riser tensioner ropes.

- Six high performance strands.

- With independent wire rope core.

- Large number of wires for increased stability.

- High fatigue resistance.