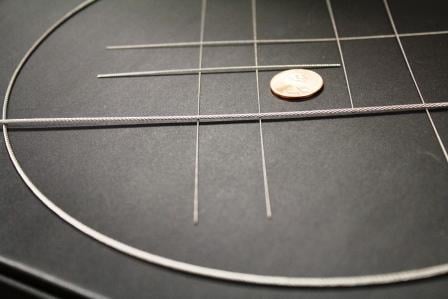

Miniature wire rope

Microlin and Posilign Miniature wire rope was developed for applications in which maximum flexibility, durability, and corrosion resistance are required within confined spaces. Critical applications such as medical devices,

electronics, aircraft interiors as well as many others have benefited from miniature wire rope and assemblies manufactured by LKS.

Microlin:

Microlin cable is available in diameters ranging from .010” to .048” with breaking strengths of up to 175 pounds. Microlin is offered bare or nylon jacketed for improved durability. We also offer a complete line of off the shelf end fittings for cable assemblies. The miniature diameters and materials of Microlin cable allow it to be routed around bulkheads or obstructions with ease while maintaining high flexibility and fatigue resistance.

Posilign:

In addition to providing the same benefits as Microlin cable, Posilign offers the elimination of constructional stretch, allowing minimal elongation while under load. Removing constructional stretch assists with more accurate adjustment and minimal secondary adjustment to cable assemblies.

| Medical Instruments | Automotive Controls |

| Automotive Controls | Commercial Applications |

| Aircraft Controls | Tagging |

| Displays | Security |

| Consumer Goods | Sporting Goods |

| Agriculture | Office Equipment |

| Orthodontics |

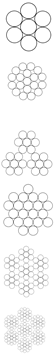

Standard Constructions

Strand

1×7: In a 1×7 strand, six outer wires are laid around the center wire. More flexible than the 1×3, it is often used for push-pull applications.1×19: In a 1×19 construction, 12 outer wires are laid around a 1×7 center. This construction is even more flexible than the 1×7 and is often used in push-pull applications.

Cable

7×3: In a 7×3 cable, six 1×3 strands are wrapped around a 1×3 center. This cable has many of the same properties as the 3×7 but is much smoother. 7×3 is a common construction for applications where a jacketed cable is needed.

7×7: In a 7×7 cable, six 1×7 strands are wrapped around a 1×7 center. This construction is one of the most commonly used in the construction industry. 7×7 cable is known for its flexibility and high cycle life.

7×19: In a 7×19 cable, six 1×19 strands are wrapped around a 1×19 center. 7×19 is the most flexible construction you can have in cable. Like the 7×7, it has a high cycle life but a lower breaking strength.If you don’t see the construction you are looking for here, contact us. As a manufacturer, we are able to make custom products all the time.

Standard Jacket Materials

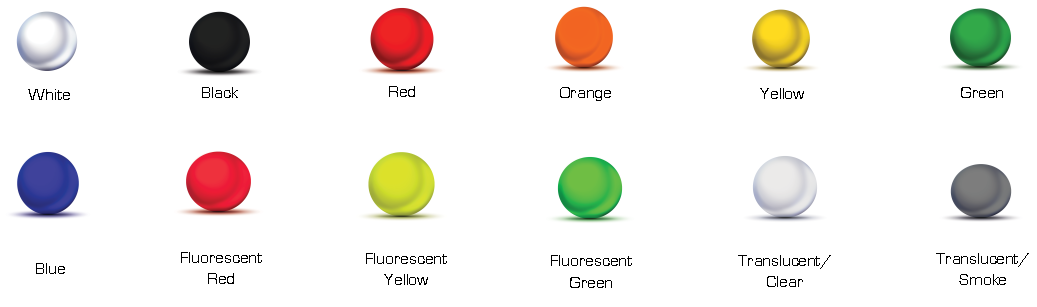

Poly-Vinyl-Chloride (PVC):

PVC is the most commonly used plastic for mechanical cable coatings. Reasonably priced and flexible, PVC carries excellent weatherability and UV resistance—something that degrades most plastics. Operating temperatures range from 30°F

(-35°C) to 180°F (80°C). Vinyl is supplied in a range of hardness and durometers—which create a spectrum from hard and stiff to soft and spongy. Color choices are nearly endless—from vivid brights and soft pastels to fluorescents and safety orange. Let us know what you need, and we can make it happen.

Nylon Series:

With wide-ranging flexibility and chemical/fatigue resistance, our nylon jackets can be tailored to fit your application. When you need a jacketed cable with a high cycle life, nylon is what you are looking for! Our Exerflex Pro® fitness cable and

MIL-DTL-83420 aircraft cable are clear illustrations of its longevity.

Miniature Stainless Wire Rope Products

| Performance Specifications | Uncoated | Plastic Coated | |||||||||

| Nominal Diameter | Construction | Min. Breaking Strength | Approx. Weight Per 100 ft. | Coated Diameter | Approx. Weight Per 100 ft. | ||||||

| in. | mm | lbs. | kg | lbs. | kg | in. | mm | lbs. | kg | ||

| 0.006 | 0.152 | 1×7 | 5 | 2.3 | 0.01 | 0.00 | Call +86-13801785300 for additional details | ||||

| 0.007 | 0.178 | 1×7 | 7 | 3.1 | 0.01 | 0.00 | |||||

| 0.009 | 0.229 | 3×7 | 10 | 4.5 | 0.02 | 0.01 | |||||

| 0.012 | 0.305 | 1×7 | 25 | 9.1 | 0.03 | 0.01 | |||||

| 0.014 | 0.356 | 7×7 | 20 | 11.8 | 0.03 | 0.01 | |||||

| 0.015 | 0.381 | 1×7 | 30 | 13.6 | 0.05 | 0.02 | 0.021 | 0.533 | 0.06 | 0.03 | |

| 0.015 | 0.381 | 1×19 | 34 | 16.7 | 0.05 | 0.02 | 0.021 | 0.533 | 0.06 | 0.03 | |

| 0.016 | 0.406 | 7×7 | 25 | 12.3 | 0.04 | 0.02 | 0.024 | 0.610 | 0.06 | 0.03 | |

| 0.017 | 0.432 | 1×7 | 40 | 19.6 | 0.06 | 0.03 | 0.027 | 0.685 | 0.08 | 0.04 | |

| 0.018 | 0.457 | 1×7 | 47 | 21.3 | 0.07 | 0.03 | 0.027 | 0.685 | 0.08 | 0.04 | |

| 0.018 | 0.457 | 7×3 | 40 | 19.6 | 0.05 | 0.02 | 0.027 | 0.610 | 0.06 | 0.05 | |

| 0.018 | 0.457 | 7×7 | 35 | 18.1 | 0.05 | 0.02 | 0.027 | 0.610 | 0.06 | 0.05 | |

| 0.018 | 0.457 | 1×19 | 46 | 20.5 | 0.05 | 0.02 | 0.030 | 0.762 | 0.14 | 0.06 | |

| 0.021 | 0.533 | 1×7 | 74 | 33.6 | 0.09 | 0.04 | 0.034 | 0.864 | 0.12 | 0.06 | |

| 0.024 | 0.610 | 1×7 | 100 | 34.0 | 0.13 | 0.06 | 0.034 | 0.864 | 0.16 | 0.07 | |

| 0.024 | 0.610 | 7×7 | 60 | 31.8 | 0.12 | 0.05 | 0.037 | 0.940 | 0.22 | 0.10 | |

| 0.027 | 0.686 | 1×7 | 125 | 45.4 | 0.16 | 0.07 | 0.037 | 0.940 | 0.24 | 0.11 | |

| 0.027 | 0.686 | 7×7 | 90 | 40.8 | 0.13 | 0.06 | 0.037 | 0.940 | 0.22 | 0.10 | |

| 0.030 | 0.762 | 7×3 | 110 | 49.9 | 0.15 | 0.07 | 0.037 | 0.940 | 0.22 | 0.10 | |

| 0.031 | 0.787 | 7×7 | 130 | 59.0 | 0.16 | 0.07 | 0.044 | 1.120 | 0.26 | 0.12 | |

| 0.042 | 1.067 | 7×7 | 200 | 90.7 | 0.35 | 0.16 | 0.063 | 1.590 | 0.65 | 0.29 | |

| 0.044 | 1.116 | 7×7 | 250 | 113.0 | 0.35 | 0.16 | 0.063 | 1.590 | 0.65 | 0.29 | |

| 0.047 | 1.194 | 7×7 | 270 | 122.0 | 0.42 | 0.19 | 0.063 | 1.590 | 0.65 | 0.29 | |

| 0.047 | 1.194 | 7×19 | 240 | 109.0 | 0.55 | 0.25 | 0.063 | 1.59 | 0.68 | 0.29 | |

** All standard products are made with 302/304/316 stainless steel. Other alloys are available upon request.

Contact us today to get more information about any of the products listed above or to get a free quote.

Standard Jacket Colors

There is another important ropes in the medical applications, we called Tungsten Wire Rope

Specifications Of Tungsten Wire Rope

Wire rope has a complex structure with many individual wires combined together. It is important to know and select the characteristics of the rope required.

1×7 Strands 1×19 Strands 7×19 Stands

Loading at room temperature and high temperature

| Dia/mm | Load at Room temperature/N | Load at High temperature/N |

| 2.5 | 6700 | 2820 |

| 2.0 | 4010 | 1800 |

| 1.8 | 3700 | 1570 |

Applications Of Tungsten Wire Rope

* Suitable for making heating wires

* Twisted wires for coating films under vacuum

* Tungsten wire for the electric light source

* Electric light parts

* Electronic device

Packaging Of Tungsten Wire Rope

Our tungsten wire rope is carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.