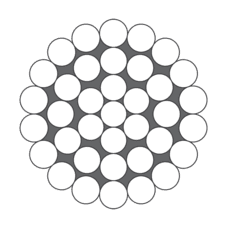

1×37 Galvanized Steel Strand

Galvanized steel strands, also called galvanized stranded wires, which are twisted together by several galvanized steel wires. Among different steel wire strands, 1 × 3, 1 × 7, 1 × 19 galvanized stranded wire are the most popular. Because they are made by means of wire drawing followed by hot-dipped galvanizing or electrical galvanizing, the surface of the strands has a layer of zinc. Therefore, the strands have extremely excellent nature, such as excellent abrasion resistance, high tensile strength and corrosion resistance.

Specification of galvanized steel strand

- Material: high carbon steel, mild steel wire.

- Wire diameter: 0.8 mm – 7.60 mm.

- Strand size: 5.4 mm – 17.80 mm.

- Length: according to the customer request.

- Finish: smooth, dimpled, indented.

- Zinc coating: according to ASTM A475 Class A, 80g/m2 – 550g/m2.

- Tensile strength: 1000 MPa – 1960 MPa.

- Standard: ASTM A363, ASTM A416, ASTM A648, EN 10138, BS 5896, AS 4671, ISO 6934, JIS G 3536, etc.

- Structure: 1 × 37, 1 × 25, 1 × 19, 1 × 7, 1 × 4, 1 × 3 and 1 × 2.

Features

- Environmental protection zinc coating.

- Thick and firm zinc coating.

- Good corrosion resistance of Class A.

- Unique anti-rust process on joints.

- Toughness maintains a long time.

- Good stability and reliability.

- A compacted structure with no crack, curve, or shift.

| Minimum Breaking Force of Strand (lb.) | ||||||

|---|---|---|---|---|---|---|

| Nominal Diameter of Strand (in.) | Number of Wires | Nominal Diameter of Coated Wires (in.) | Approx. Wt. Of Strand (lb/1000 ft.) | Utilities Grade | High Strength Grade | Extra-High Strength Grade |

| 3/16 | 7 | 0.062 | 73 | — | 2850 | 3990 |

| 7/32 | 7 | 0.072 | 98 | — | 3850 | 5400 |

| 1/4 | 7 | 0.08 | 121 | — | 4750 | 6650 |

| 9/32 | 7 | 0.093 | 164 | — | 6400 | 8950 |

| 5/16 | 7 | 0.104 | 205 | — | 8,000* | 11,200* |

| 3/8 | 7 | 0.12 | 273 | 11,500* | 10,800* | 15,400* |

| 7/16 | 7 | 0.145 | 399 | 18000 | 14,500* | 20,800* |

| 1/2 | 7 | 0.165 | 517 | 25000 | 18,800* | 26,900* |

| 1/2 | 19 | 0.1 | 504 | — | 19100 | 26700 |

| 9/16 | 7 | 0.188 | 671 | — | 24500 | 35000 |

| 9/16 | 19 | 0.113 | 637 | — | 24100 | 33700 |

| 5/8 | 7 | 0.207 | 813 | — | 29600 | 42400 |

| 5/8 | 19 | 0.125 | 796 | — | 28100 | 40200 |

| 3/4 | 19 | 0.15 | 1155 | — | 40800 | 58300 |

| 7/8 | 19 | 0.177 | 1581 | — | 55800 | 79700 |

| 1 | 19 | 0.2 | 2073 | — | 73200 | 104500 |

| 1 1/8 | 37 | 0.161 | 2691 | — | 91600 | 130800 |

| 1 1/4 | 37 | 0.179 | 3248 | — | 113600 | 162200 |

| *ASTM A 363 (Weldless) is also available in these sizes and grades upon request. |

Applications

Galvanized Steel Strand has a long history of service to the power transmission industry, the pre-engineering building industry, the construction industry, fishing industry, municipalities and cable structures, etc.

- Power transmission industry: messenger wires, guy wires, core wires, earth wires, telecommunication cables, barrier cable, etc.

- Construction industry: high-rise and other commercial structures, multi-level parking garages, structure cables, etc.

- Road and bridge structures: highway and railway viaducts, suspension bridges and cable-stayed bridges, express way fencing, etc.

Precautions

- Surface protection: no folding marks, no scratches, no defects such as broken, crushed, and hard to bend.

- The surface of galvanized steel strand should keep away from oil, dirt, water and other impurities.

- The ribs on strand surface should be consecutive, no crack and spalling phenomena.