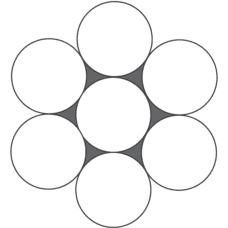

Galvanized steel strand, also called galvanized stranded wires, which are twisted together by several galvanized steel strand. Among different galvanized steel strand, 1 × 3, 1 × 7, 1 × 19 galvanized stranded wire are the most popular. Because they are made by means of wire drawing followed by hot-dipped galvanizing or electrical galvanizing, the surface of the strands has a layer of zinc. Therefore, the strands have extremely excellent nature, such as excellent abrasion resistance, high tensile strength and corrosion resistance.

Specification

- Material: high carbon steel, mild steel wire.

- Wire diameter: 0.8 mm – 7.60 mm.

- Strand size: 5.4 mm – 17.80 mm.

- Length: according to the customer request.

- Finish: smooth, dimpled, indented.

- Zinc coating: according to ASTM A475 Class A, 80g/m2 – 550g/m2.

- Tensile strength: 1000 MPa – 1960 MPa.

- Standard: ASTM A363, ASTM A416, ASTM A648, EN 10138, BS 5896, AS 4671, ISO 6934, JIS G 3536, etc.

- Structure: 1 × 37, 1 × 25, 1 × 19, 1 × 7, 1 × 4, 1 × 3 and 1 × 2.

Typical applications:

- Overhead ground wire strand for power transmission lines

- Messenger strand for telephone and CATV lines

- Guy strand for power distribution poles, telephone poles and microwave and radio towers

- Wind bracing in pre-engineered buildings

- Barrier cable and guard rail strand

- Other guying applications where small size, high strength and corrosion resistance are necessary

It meets or exceeds ASTM A475 and CSA-G12 Specification. It combines the strength of high carbon steel wire with the excellent corrosion resistance of class A, hot-dip zinc coating. It is normally recommended to power transmission industry, construction industry, communication industy and other guying applications

ASTM A 475

| Nominal Dia of Strand | Number of Wires in Strands | Nominal Dia of Coated Wires | Weight of Strand, | Minimum Breaking Strength of Strand, LBS | ||

| Inch (mm) | Inch (mm) | Lb/1000ft (Kg/1000m) | Utilities Grade | High Strength Grade | Extra-High Strength Grade | |

| 1/4 (6.35) | 7 | 0.080 (2.03) | 121 (180) | – | 4,750 | 6,650 |

| 9/32 (7.14) | 7 | 0.093 (2.36) | 164 (244) | 4,600 | 6,400 | 8,950 |

| 5/16 (7.94) | 7 | 0.104 (2.64) | 205 (305) | – | 8,000 | 11,200 |

| 5/16 (7.94) | 7 | 0.109 (2.77) | 225 (335) | 6,000 | – | – |

| 3/8 (9.52) | 7 | 0.120 (3.05) | 273 (406) | 11,500 | 10,800 | 15,400 |

| 7/16 (11.11) | 7 | 0.145 (3.68) | 399 (594) | 18,000 | 14,500 | 20,800 |

| 1/2 (12.70) | 7 | 0.165 (4.19) | 517 (769) | 25,000 | 18,800 | 26,900 |

| 1/2 (12.70) | 19 | 0.100 (2.54) | 504 (750) | – | 19,100 | 26,700 |

| 9/16 (14.29) | 7 | 0.188 (4.78) | 671 (999) | – | 24,500 | 35,000 |

| 9/16 (14.29) | 19 | 0.113 (2.87) | 637 (948) | – | 24,100 | 33,700 |

| 5/8 (15.88) | 7 | 0.207 (5.26) | 813 (1210) | – | 29,600 | 42,400 |

| 5/8 (15.88) | 19 | 0.125 (3.18) | 796 (1185) | – | 28,100 | 40,200 |

| 3/4 (19.05) | 19 | 0.150 (3.81) | 1,155 (1719) | – | 40,800 | 58,300 |

| 7/8 (22.22) | 19 | 0.177 (4.50) | 1,581 (2553) | – | 55,800 | 79,700 |

| 1 (25.40) | 19 | 0.200 (5.08) | 2,073 (3085) | – | 73,200 | 104,500 |

CSA-G12 CLASS A ZINC COATING (METRIC)

| Diameter | Number of wires & diameter | Approx. Metallic Area | Weight | Minimum Breaking Load – kN | ||

| (mm) | (mm) | (sq. mm) | (kg/1000m) | Grade 1100 | Grade 1300 | Grade 1500 |

| 5 | 7 x 1.70 | 15.9 | 130 | 16.5 | 19.5 | 22.5 |

| 6 | 7 x 2.10 | 24.2 | 190 | 25.0 | 30.0 | 34.5 |

| 7 | 7 x 2.40 | 31.7 | 250 | 33.0 | 39.0 | 45.0 |

| 8 | 7 x 2.80 | 43.1 | 340 | 45.0 | 53.0 | 61.5 |

| 9 | 7 x 3.00 | 49.5 | 390 | 52.0 | 61.0 | 70.5 |

| 10 | 7 x 3.60 | 71.3 | 560 | 74.5 | 88.0 | 101.5 |

| 12 | 7 x 4.20 | 97.0 | 760 | 101.0 | 120.0 | 138.0 |

CSA-G12 CLASS A ZINC COATING (IMPERIAL)

| Diameter | Number of wires & diameter | Approx. Metallic Area | Weight | Minimum Breaking Load – lbs | ||

| (Inches) | (Inches) | (sq. Inches) | (lbs/1000ft) | Grade 160 | Grade 180 | Grade 220 |

| 3/16″ | 7 x 0.065 | 0.02 | 79 | 3500 | 4000 | 4800 |

| 1/4″ | 7 x 0.083 | 0.04 | 129 | 5700 | 6400 | 7900 |

| 9/32″ | 7 x 0.095 | 0.05 | 169 | 7500 | 8500 | 10300 |

| 5/16″ | 7 x 0.109 | 0.07 | 223 | 9900 | 11100 | 13600 |

| 3/8″ | 7 x 0.120 | 0.08 | 270 | 12000 | 13500 | 16500 |

| 7/16″ | 7 x 0.144 | 0.11 | 389 | 17300 | 19500 | 23800 |

| 1/2″ | 7 x 0.165 | 0.15 | 511 | 22700 | 25500 | 31200 |

| 5/8″ | 7 x 0.207 | 0.24 | 813 | 35800 | 40200 | 49200 |