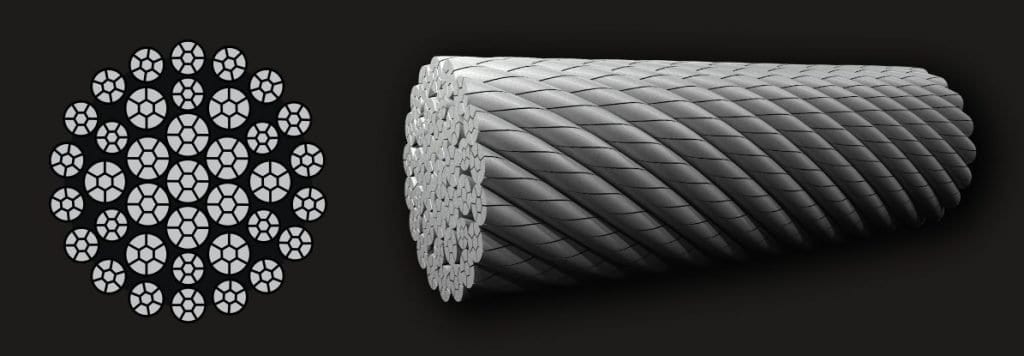

37X7 (6/1) Compacted – Non Rotating Steel Wire Rope

This compacted wire rope is available in both galvanised and ungalvanised finish with either ordinary or langs lay. The construction family includes: 32X7, 34X7 and 37X7.

Depending upon your requirement for higher breaking load or better wear characteristics, these wire ropes are available in different finishes and lubrications, as well as being available with plastic impregnated.

- Applications

- Offshore crane rope

- Deck crane rope

- Pillar crane rope

- Whip hoist rope

- Main hoist rope

- Crane rope

| Breaking Loads | |||||

|---|---|---|---|---|---|

| Nominal Diameter | Approximate Mass | Minimum Breaking Loads | |||

| 1770 Mpa | 1960 Mpa | ||||

| [mm] | [kg/m] | [kN] | [Kg] | [kN] | [Kg] |

| 14 | 0.95 | 154 | 15,708 | 171 | 17,442 |

| 15 | 1.09 | 177 | 18,054 | 196 | 19,992 |

| 16 | 1.25 | 203 | 20,706 | 225 | 22,950 |

| 18 | 1.58 | 257 | 26,214 | 285 | 29,070 |

| 19 | 1.78 | 290 | 29,580 | 321 | 32,742 |

| 20 | 1.95 | 318 | 32,436 | 352 | 35,904 |

| 21 | 2.15 | 349 | 35,598 | 387 | 39,474 |

| 22 | 2.37 | 385 | 39,270 | 426 | 43,452 |

| 23 | 2.56 | 416 | 42,432 | 461 | 47,022 |

24 | 2.81 | 457 | 46,601 | 506 | 51,612 |

| 25 | 3.10 | 504 | 51,510 | 558 | 56,916 |

26 | 3.30 | 537 | 54,774 | 595 | 60,690 |

28 | 3.80 | 618 | 63,036 | 685 | 69,870 |

| 29 | 4.10 | 667 | 68,034 | 738 | 75,276 |

30 | 4.45 | 724 | 73,848 | 802 | 81,804 |

32 | 4.96 | 806 | 82,212 | 892 | 90,984 |

37×7 Steel Wire Ropes for Spin & Rotation Resistance

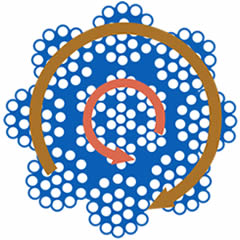

Rotation resistant wire rope is composed of multi-layers of strands for minimizing the tendency to spin and rotation.

Rotation resistant wire rope refers to a series of steel ropes which minimizes the tendency to spin or rotation under load. These wire ropes boast special design – the outer layer is twisted in the reverse direction of inner layers for counteracting torsional forces generated from multi-layers of strands.

To achieve the resistance against the spin and rotation, all wire ropes are composed of at least two layers of strands. In general, more layers a rotation resistant wire rope has, more resistance it will boast. For example, 2-layer ropes is much easier to spin and rotate than 3-layer ones. Meanwhile, if one end of free rotation is allowed, 2-layer rope can only develop 55% to 75% of its breaking strength comparing with 95% to 100% of 3-layer ropes.

According to characteristics of rotation resistant wire ropes, three categories are supplied by our company to suit your different needs:

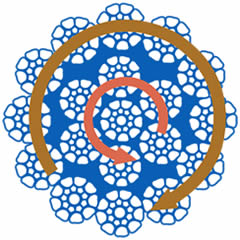

Spin resistant 2 layers & 8 to 10 outer strands

Rotation resistant 2 layers & 11 to 13 outer strands

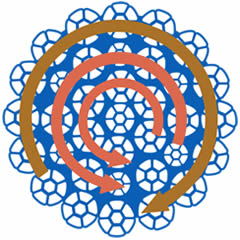

Non-rotating 3 layers & 14 or more outer strands

Normally, 2-layer spin and rotation resistant wire ropes can meet your needs of low and medium rotation resistance.

The 3-layer rope with more outer strands is capable to distribute more

radial pressure onto inner layers and ideal for larger mobile such as all tower cranes.

Application:

- Serving as single part lines.

- Whip hoist ropes.

- Deck crane ropes.

- Off shore crane ropes.

- Pillar crane ropes, etc.

Detail:

- Surface: bright or galvanized finish.

- Lay style: regular or lang lay as your requirements.

- Available with plastic impregnated.

- Outer strands: 5 to 20 strands.