Gas & oilfield wire ropes with higher breaking strength, excellent flexibility, better rotation resistance and extended lifespan are urgently needed with the development of gas and oil industry. These steel wire rope are designed to increase the productivity on rigs and minimize downtime.

For the oil and gas industry, finding and accessing new sources of energy depends on global availability of extraordinarily tough drilling lines that let you explore and extract resources buried deep beneath the surface. Union drilling lines are like our engineers and personnel – with you day-in, day-out helping you produce on the rig. Offshore, land, workover or whatever the rig may be – we know the right rope for your application. You can count on Union’s outstanding quality and support wherever your rig may be.

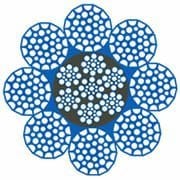

AtLKS, as a Chinese leading steel cable supplier, we offer 8-strand wire ropes with compacted and plastic impregnated constructions. Compacted outer strands give this hoisting and pulling wire high strength, robustness and wear resistance. Plastic impregnation of the core between outer strands improves performance of the stranded rope in case of heavy duty applications.

Feature:

- For offshore applications.

- Eight compacted strands.

- Plastic impregnated core.

- Greater surface area than GOWR-629C.

- Less sheave wear.

- High strength.

Technical Parameters of the Steel Wire Rope

| Nominal diameter | Weight (for reference) | Nominal tensile strength ( Mpa ) | ||||

| 1960 | 2160 | |||||

| Minimum breaking load | ||||||

| mm | Kg/m | KN | Ton | KN | Ton | |

| 6.00 | 0.17 | 32 | 3 | 34 | 3 | |

| 7.00 | 0.23 | 44 | 4 | 46 | 5 | |

| 8.00 | 0.30 | 57 | 6 | 60 | 6 | |

| 9.00 | 0.38 | 72 | 7 | 75 | 8 | |

| 10.00 | 0.47 | 89 | 9 | 93 | 10 | |

| 11.00 | 0.57 | 108 | 11 | 113 | 12 | |

| 12.00 | 0.68 | 128 | 13 | 134 | 14 | |

| 13.00 | 0.80 | 151 | 15 | 157 | 16 | |

| 14.00 | 0.93 | 175 | 18 | 183 | 19 | |

| 15.00 | 1.06 | 200 | 20 | 210 | 21 | |

| 16.00 | 1.21 | 228 | 23 | 238 | 24 | |

| 17.00 | 1.36 | 257 | 26 | 269 | 27 | |

| 18.00 | 1.53 | 289 | 29 | 302 | 31 | |

| 19.00 | 1.70 | 322 | 33 | 336 | 34 | |

| 20.00 | 1.89 | 356 | 36 | 373 | 38 | |

| 22.00 | 2.28 | 431 | 44 | 451 | 46 | |

| 24.00 | 2.72 | 513 | 52 | 537 | 55 | |

| 26.00 | 3.19 | 602 | 61 | 630 | 64 | |

| 28.00 | 3.70 | 698 | 71 | 730 | 7 5 | |

| 30.00 | 4.25 | 802 | 82 | 838 | 86 | |

| 32.00 | 4.83 | 912 | 93 | 954 | 97 | |

| 34.00 | 5.46 | 1030 | 105 | 1077 | 110 | |

| 36.00 | 6.12 | 1155 | 118 | 1207 | 123 | |

| 38.00 | 6.82 | 1286 | 131 | 1345 | 137 | |

| 40.00 | 7.55 | 1425 | 145 | 1490 | 152 | |

Note:

1. The data in this table is for reference purposes only with no guarantee or warranty as to its accuracy. The actual parameters may be varied due to different testing methods and influence by weather, temperature, humidity, and other environmental factors.

2. Not only does Junwei manufacture steel wire ropes based on industrial standard, but we also offer custom production as per your requirements. Please consult with us for details.