MWR-619S Mining Wire Rope

Mining Industry demands the best in class wire rope, which can perform under one of the most adverse working conditions in the world.

LKS, an Industry leader in mining rope segment, provides ropes with excellent breaking load capacity and higher resistance to fatigue, wear, and abrasion helping users to achieve reduced downtime, longer life, and low maintenance cost.

LKS Mining ropes find applications in the multiple areas including

- Surface Mining

- Dragline: Hoist rope, Drag rope, Dump rope, Pendant rope

- Shovel: Hoist rope, Crowd rope/Retract rope, Trip rope, Pendant rope

- Under Ground Mining

- Winder: Hoist rope, Balance rope, Guide rope

- Chair lift/ Man riding haulage rope

- Haulage/Scrapper rope

- Aerial transportation rope

- Cable belt conveyor rope

Size Range:

16 mm to 143 mm

(0.6299 inch to 5.6299 inch)

Feature:

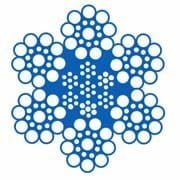

- 6 × 19 Seale strands.

- Independent wire rope core.

- Excellent resistance against abrasion and crushing.

- Rope diameter: 6.5mm to 70mm.

Product Parameter

| Rope Nominal Diameter (mm) | Approx. Weight (kg/100m) | Nominal Tensile Strength(MPa) | |||||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | 2160 | ||||||||||

| Minimum Breaking Strength(kN) | |||||||||||||||

| Natural Fiber Core | Synthetic Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | |

| 12 | 53.1 | 51.8 | 58.4 | 74.6 | 80.5 | 79.4 | 85.6 | 84.1 | 90.7 | 88.9 | 95.9 | 93.1 | 100 | 103 | 111 |

| 13 | 62.3 | 60.8 | 68.5 | 87.6 | 94.5 | 93.1 | 100 | 98.7 | 106 | 104 | 113 | 109 | 118 | 120 | 130 |

| 14 | 72.2 | 70.5 | 79.5 | 102 | 110 | 108 | 117 | 114 | 124 | 121 | 130 | 127 | 137 | 140 | 151 |

| 16 | 94.4 | 92.1 | 104 | 133 | 143 | 141 | 152 | 150 | 161 | 158 | 170 | 166 | 179 | 182 | 197 |

| 18 | 119 | 117 | 131 | 168 | 181 | 179 | 193 | 189 | 204 | 200 | 216 | 210 | 226 | 231 | 249 |

| 20 | 147 | 144 | 162 | 207 | 224 | 220 | 238 | 234 | 252 | 247 | 266 | 259 | 279 | 285 | 308 |

| 22 | 178 | 174 | 196 | 251 | 271 | 267 | 288 | 283 | 305 | 299 | 322 | 313 | 338 | 345 | 372 |

| 24 | 212 | 207 | 234 | 298 | 322 | 317 | 342 | 336 | 363 | 355 | 383 | 373 | 402 | 411 | 443 |

| 26 | 249 | 243 | 274 | 350 | 378 | 373 | 402 | 395 | 426 | 417 | 450 | 437 | 472 | 482 | 520 |

| 28 | 289 | 282 | 318 | 406 | 438 | 432 | 466 | 458 | 494 | 484 | 522 | 507 | 547 | 559 | 603 |

| 30 | 332 | 324 | 365 | 466 | 503 | 496 | 535 | 526 | 567 | 555 | 599 | 582 | 628 | 642 | 692 |

| 32 | 377 | 369 | 415 | 531 | 572 | 564 | 609 | 598 | 645 | 632 | 682 | 662 | 715 | 730 | 787 |

| 34 | 426 | 416 | 469 | 599 | 646 | 637 | 687 | 675 | 728 | 713 | 770 | 748 | 807 | 824 | 889 |

| 36 | 478 | 466 | 525 | 671 | 724 | 714 | 770 | 757 | 817 | 800 | 863 | 838 | 904 | 924 | 997 |

| 38 | 532 | 520 | 585 | 748 | 807 | 796 | 858 | 843 | 910 | 891 | 961 | 934 | 1010 | 1030 | 1110 |

| 40 | 590 | 576 | 649 | 829 | 894 | 882 | 951 | 935 | 1010 | 987 | 1070 | 1030 | 1120 | 1140 | 1230 |

| 42 | 670 | 654 | 737 | 914 | 986 | 972 | 1049 | 1030 | 1112 | 1088 | 1174 | 1141 | 1231 | — | — |

Note : Steel wire min. aggregate breaking strength = Min. breaking strength of steel wire rope× 1.214(fiber Core) or 1.308(steel core)