LKS Crane Wire Rope in 1200TONS Crane

In the afternoon of June 8, with the 350 ton crane arm slowly put back to the shelf, the installation of crane wire rope for 1200 ton pile around crane and 350 ton pile winding crane of H6018 ship was successfully completed, and the maximum work before the tilt test of the project was successfully completed.

The deck of H6018 ship is equipped with two pile winding cranes, including five 1200 ton crane wire rope, two luffing wire rope of 50 * 1500 meters, two main hook wire ropes of 58 * 2000 meters, and one auxiliary hook wire rope of 50 * 1000 meters; the 350 ton crane has three luffing wire rope of 42 * 900 meters * 1, the main hook wire rope of 42 * 1200 meters * 1, and the auxiliary hook wire rope of 42 * 300 meters * 1.

The installation of the above crane wire rope involves 690V main power supply of the crane, ballast adjustment of the ship and installation of the sliding contact line. Among them, the steel wire installation of the 1200 ton crane needs floating berthing, and the floating berthing needs to reserve a distance of 70 meters from the stern. The ship needs to be moved, and the cross operation with the pile leg is carried out, and the extreme weather is also faced…

Due to the heavy workload, complex process and many cross operations, and the ship ballast can not be used, it is difficult to adjust it manually. According to the past experience, the period needs one month, which will not meet the requirements of tilt test.

On May 20, the project team took the lead to organize ZPMC manufacturers, material department, general assembly department and other units to hold a special meeting, which launched a “battle against the clock” to ensure the node.

Retrospection

1、 Set up a temporary group to tackle difficulties and overcome difficulties

At the symposium, a temporary group for tackling difficulties was established, which was composed of project team, design department I, material department, commissioning operation area, ship loading operation area, electric loading operation area, mechanical loading operation area, technical construction method personnel, lifting workers, erection workers and other personnel. The division of labor was clear, the responsibilities were assigned to each person, and all the personnel made concerted progress;

2、 Strong plan

Formulate a special plan with the morning, afternoon and evening shift as the time points, and make it clear that the work will be completed on June 8. The node is the order, and the plan will not be relaxed;

3、 Focus on planning:

The start of the project coincides with the two sessions and the safety month. The rope threading process involves factors such as floating state adjustment, high-altitude operation, extreme weather and other factors. Therefore, it is planned to adjust the operation to the daytime. The shift is carried out at noon to race against the time. During this period, the generator characteristic test and crane cross operation, peak stagger planning is particularly critical. At 5:30 a.m. every day, the commissioning operation area is in place, the generator power supply is turned on, the Zhenhua construction personnel are in place to start operation, the machine installation personnel keep on adding water and drainage, waiting for ballast adjustment, and the gantry crane is on duty for 24 hours at any time;

4、 Dare to innovate:

Since the installation of the sliding contact line of the 1200 ton crane involves professional manufacturers, the installation cycle takes about 10 days, which can not meet the planned demand. At the meeting, it was immediately decided to use the temporary power line for bridging. In the commissioning operation area, the cable was constantly searched and collected, and the lunch break was actively given up to complete the temporary cable bridging work.

Overview of operation

From May 21 to 23, 1200 tons of electrified idling inspection and luffing crane wire rope installation

From May 25 to 31, 350 ton sliding contact line installation, medium voltage cable withstand voltage inspection, idling inspection, h6018 ship moving

From June 01 to June 06, the installation of 1200 tons of main and auxiliary crane steel wire ropes was completed

June 07-08 350 tons of main and auxiliary crane wire rope installation completed

The above series of data are created by the joint efforts of all staff of H6018 project team after half a month’s hard work, which shortens the planned one month cycle to 18 days and compresses a full 12 days.

Here show crane wire rope specification:

| No. | Description | Unit | packing |

|---|---|---|---|

| 1 | Wire Rope Ф24mm 32×7-Dy formed strands, galvanized steel right hand lay, Tensile grade of steel wire: 2160N/mm2 M.B.L: 551,4KN | m | 1000m/ Reel Packed: wooden reel. |

| 2 | Wire Rope Ф20mm 32×7- galvanized steel right hand lay, Tensile grade of steel wire: 2160N/mm2 M.B.L: 389.0KN | m | 1000m/ Reel Packed: wooden reel. |

| 3 | Wire Rope Ф 39.5mm. 6×36- preformed, galvanized steel, RHO, Tensile grade. of steel wire: 1770N/mm2. M.B.L: 912.00KN. | m | 1000m/Reel, Packed: steel reel. |

Crane Wire Ropes for Hoisting & Lifting

Crane wire ropes play an important role in ensuring a smooth conduct of work processes in harbors, off-shore platforms or various other applications where cranes are needed. Whether you need tower crane ropes or offshore crane ropes, galvanized or stainless steel ropes, you will find the optimal solution in our company.

High resistant to corrosion.Features:

- Excellent ductility for optimal fatigue properties on rope level.

- Highest breaking strength leading to outperforming steel crane wire ropes.

- Excellent impact resistance owing to its radially elastic rope structure for absorbing dynamic force easily.

- Superb flexibility ensures excellent spooling conditions in multiple layer winding and all hoisting processes.

- High cost-effectiveness taking advantages of its strong and durable structure to reduce downtime and maintenance cost.

- Rotating and rotation resistant ropes are available.

- Optional compacted and non-compacted ropes.

Details:

- Material: high carbon steel wire, galvanized steel wires or stainless steel wires.

- Standard: complying with EN-10264 or other custom specs.

- Tensile strength: 1370N/mm2 up to 2260N/mm2.

- Coating: bright phosphate wire, galvanized wire or other custom coatings.

- Wire diameter: 0.3mm to 4mm or thicker diameter upon request.

- Structure: rotating & rotation resistant wire ropes, compacted & non-compacted wire ropes.

- crane wire rope standards

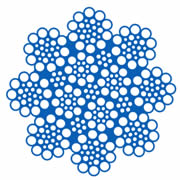

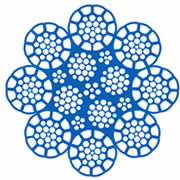

CWR-826 WS

Feature:

- Eight regular strands

- Parallel lay structure.

- Fully lubricated.

- Non-rotating.

- Application: electrical hoist, twin hoist, lifting device.

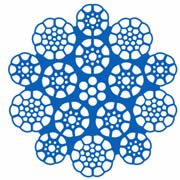

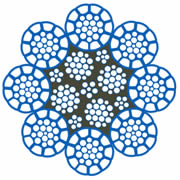

CWR-10 Compacted

Feature:

- Ten compacted outer strands

- Parallel lay structure.

- Fully lubricated.

- Non-rotating

- Application: electrical hoist, twin hoist, lifting device. Not suitable for overhead cranes and using with swivels.

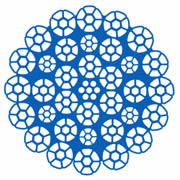

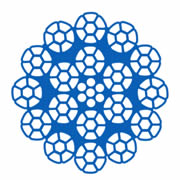

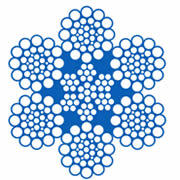

CWR-347Compacted

Feature:

- Thirty-four compacted strands.

- Low rotation.

- Optional plastic encapsulated core.

- Application: tower crane, electrical hoist, mobile crane, boom crane, offshore crane and overhead crane.

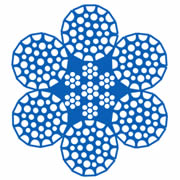

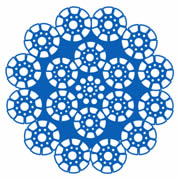

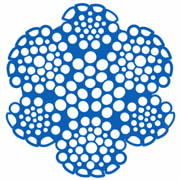

CWR-636 Compacted

Feature:

- Six compacted strands.

- Non-rotating.

- Optional plastic encapsulated core.

- Excellent crush resistant.

- Application: container crane, tower crane, boom crane, unloader crane, dockside cranes, offshore crane and overhead crane.

CWR-826 Compacted

CWR-826 Compacted

Feature:

- Eight compacted strands.

- Parallel-laid structure.

- Excellent crush resistance.

- Extremely high breaking force.

- Applications: boom crane, dockside cranes, offshore cranes and overhead cranes.

.

CWR-826 Plastic injected

CWR-826 Plastic injected

Feature:

- Eight compacted strands.

- Plastic encapsulated core.

- Ideal for multi-layer coiling.

- Reduced stretch.

- Application: boom crane, unloader crane, dockside crane, offshore crane and overhead crane.

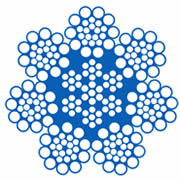

CWR-187 Compacted

CWR-187 Compacted

Feature:

- Eighteen compacted strands.

- Optional plastic encapsulated core.

- Rotation resistant.

- Application: tower crane, mobile crane, boom crane, dockside crane, offshore crane and overhead crane.

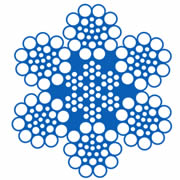

CWR-1819 Compacted

CWR-1819 Compacted

Feature:

- Eighteen compacted strands.

- Rotation resistant.

- Ideal for single-fall and multi-reeve applications.

- Application: offshore crane, mobile crane, overhead crane.

CWR-637 WS

CWR-637 WS

Feature:

- Six strands. .

- Durable design.

- High flexibility.

- Application: container crane, clamshell crane, tower crane, mobile crane and overhead crane.

.

CWR-626 WS

CWR-626 WS

Feature:

- Six strands.

- Good balance between wear resistance and flexibility.

- Fully lubricated.

- Application: container crane, tower crane, mobile crane, overhead crane and offshore crane.

CWR-6 Swaged

CWR-6 Swaged

Feature:

- Six special wire strands.

- Hammer swaged for high damage resistance.

- Smooth surface area reduces wear of sheaves and drums.

- Application: container crane, tower crane, offshore crane and clamshell crane.

CWR-728 Seale

CWR-728 Seale

Feature:

- Seven outer strands.

- Good spooling in single layer & multi-layer winding applications.

- Application: overhead crane and various high cycle applications.

Tips:

When you are picking up crane wire ropes, make sure that the breaking strength of new wire ropes is five times the sizes of the largest load for lifting applications and three times for pulling applications.